PHOTO

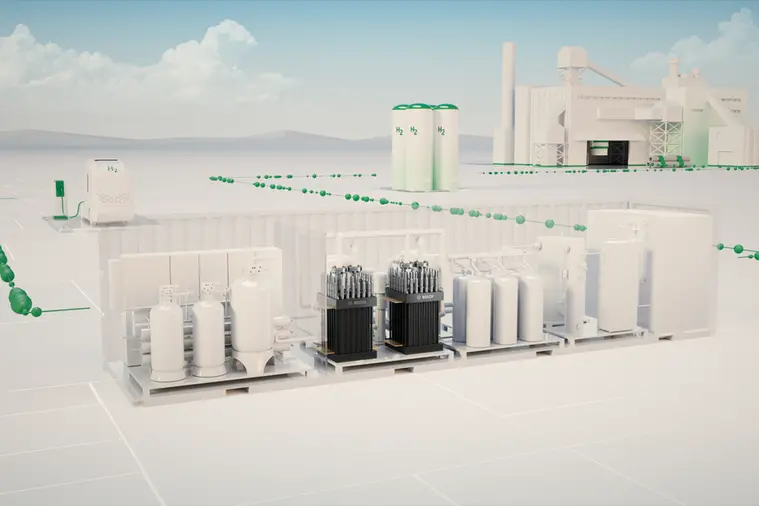

Green hydrogen is indispensable for a climate-neutral world. Whether in transportation, buildings, or the manufacturing industry – it makes sense to use it in nearly every sector. Along the entire hydrogen value chain, Bosch is developing technologies for the production, compression, storage, and use of hydrogen.

It all starts with smart technologies for hydrogen production. For this purpose, Bosch is developing the electrolysis stack, the heart of an electrolyzer. The stack comprises more than 100 electrolysis cells that use electricity to split water into oxygen and hydrogen. It is designed for an output of 1.25 megawatts. That is equivalent to the production of 23 kilograms of H2 per hour. On the hydrogen side, the resulting pressure is more than 30 bar. The Bosch electrolysis stack is suitable for use in smaller-scale plants all the way up to large gigawatt-scale plants. It is expected to be market-ready from 2025. First pilot projects with customers are in preparation for this year. In addition, Bosch is planning to combine the electrolyzer stack with a control unit, power electronics, and various sensors to create a “smart electrolysis module.” These elements are designed to be compatible and save space, and optimize systems efficiency, reliability, installation, and setup.

At World Future Energy Summit 2024 the company is providing general insights into the hydrogen portfolio of products and services and sets focus on the Bosch PEM electrolysis stack.