PHOTO

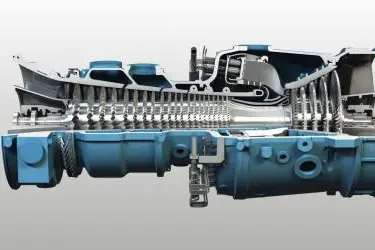

Abu Dhabi, UA: GE Power has enhanced the operational efficiency and performance of ADNOC Refining’s Ruwais General Utilities Plant with the implementation of its MXL2 upgrade solution on two GE 13E2 gas turbines.

The technology upgrade has increased the total output of the turbines by up to 23 megawatts (MW) using the same amount of fuel. It has also enhanced the availability of each turbine by an additional 6 days per annum by extending the duration between gas turbine maintenance intervals, thus leading to lower operational costs. Moreover, the upgrade solution will help deliver significant environmental benefits, preventing up to 18,000 tons of annual carbon dioxide emissions.

ADNOC Refining supplies a diversified range of petroleum products, including liquefied petroleum gas (LPG), naphtha, gasoline, jet fuel, gas oil and base oils, fuel oil, petrochemical feedstock and propylene, in addition to specialty products such as carbon black and anode coke. The Ruwais General Utilities Plant has an installed base of four GE 13E2 units that can generate up to 650 MW of power that is an essential input for the company’s production processes.

“ADNOC Refining has grown into the world’s fourth largest refinery through a strong focus on building the efficiency and sustainability of its operations and GE is honored to work with the company,” said Joseph Anis, President & CEO of GE’s Power Services and Gas Power Systems businesses in the Middle East, North Africa and South Asia. “Deploying the MXL2 solution, which combines GE’s latest technology developments and over 10 million operating hours of GT13E2 fleet experience, will support ADNOC Refining in lowering the costs of production per megawatt of power, increasing the availability of their assets and reducing environmental impact.”

In June 2018, GE had announced the new MXL2 with Additive Manufactured Performance (AMP), a part of GE’s Fleet360* total plant solutions. It is the world’s first upgrade solution for GE’s GT13E2 gas turbines that uses key components manufactured using additive technology. The addition of additive manufactured parts into the MXL2 solution represents a turning point in the global power generation industry and confirms GE’s commitment to keep its mature fleets competitive in today’s very dynamic marketplace. The new technology can help gas plant power producers save up to $2 million in fuel annually, while opening up the potential for additional revenue of up to $3 million annually in new power capacity.

© Press Release 2019Disclaimer: The contents of this press release was provided from an external third party provider. This website is not responsible for, and does not control, such external content. This content is provided on an “as is” and “as available” basis and has not been edited in any way. Neither this website nor our affiliates guarantee the accuracy of or endorse the views or opinions expressed in this press release.

The press release is provided for informational purposes only. The content does not provide tax, legal or investment advice or opinion regarding the suitability, value or profitability of any particular security, portfolio or investment strategy. Neither this website nor our affiliates shall be liable for any errors or inaccuracies in the content, or for any actions taken by you in reliance thereon. You expressly agree that your use of the information within this article is at your sole risk.

To the fullest extent permitted by applicable law, this website, its parent company, its subsidiaries, its affiliates and the respective shareholders, directors, officers, employees, agents, advertisers, content providers and licensors will not be liable (jointly or severally) to you for any direct, indirect, consequential, special, incidental, punitive or exemplary damages, including without limitation, lost profits, lost savings and lost revenues, whether in negligence, tort, contract or any other theory of liability, even if the parties have been advised of the possibility or could have foreseen any such damages.